Are you tired of buying excavator parts that break down right after the product warranty expires? The reason this keeps happening is that most suppliers in the construction industry offer the bare minimum coverage. They're counting on you not to read the fine print. We decided to do things differently. Our warranty backs every part we sell for longer than anyone else because we've tested the quality enough to stand behind it. If you're wondering how we built the longest warranty in the business, here's what we'll cover today: the difference between written warranties and implied warranty protection, our quality control testing process, why cheap parts fail so fast, and what actually happens when you need warranty service. At the end of the

Five Essential Parts Every Excavator Owner Should Always Keep On Hand

Every excavator relies on a handful of components that determine how well it operates day to day (and whether you're dealing with downtime or smooth sailing). Those parts include the hydraulic pump, final drive, swing motor, control valves, and undercarriage components like track rollers and idlers. In this article, we're going to walk through each part, explain what it does, and help you spot early warning signs before something breaks. If you're running equipment on-site or managing a fleet, partnering with a leading supplier makes sourcing reliable parts far easier. Let's start with the hydraulic pump, which powers nearly every movement your excavator makes. Hydraulic Hoses and Fittings Hydraulic hoses fail more frequently than almost any other excavator component because they're constantly flexing under

How New York Construction Companies Rely on One Supplier More Than Any Other

Every day your excavator sits idle costs you money. For New York construction companies, equipment breakdowns don't wait for convenient timing. When you're juggling multiple vendors for parts, each delay adds up to lost crew hours and missed deadlines. So, why do most companies spread their equipment sourcing across several suppliers? Well, from our point of view, it’s because they think it's less risky. In reality, the opposite happens. More vendors mean more communication gaps, inconsistent quality, and longer wait times when you need parts urgently. This article shows you why New York construction companies are turning to single-supplier partnerships. You'll see how consolidating equipment sourcing saves time and money, prevents costly downtime, and simplifies operations in a city where downtime is

The Real Cost of Buying Cheap Machinery Parts

You found a great deal on excavator tracks online. The price was half what everyone else charges, so you ordered a set and installed it. But three months later, they're already falling apart. If that sounds familiar, you’ve run into one of the most common risks in the industry. When a budget component fails early, equipment breakdown is usually just the beginning. Unplanned downtime follows, schedules get blown, and clients start asking questions you don’t want to answer. At Bites Off Broadway, we've spent over 30 years supplying undercarriage parts and machinery components to contractors across New York. We've seen what cheap parts do to equipment, and we've helped operators dig out of those holes more times than we can count. That's why

How the Parts Shortage Changed Equipment Supply Chains

The parts shortage forced construction companies to completely rebuild their supply chains. Between 2020 and 2023, lead times jumped from weeks to months, costs skyrocketed, and projects stalled because of missing parts. We’re Bites Off Broadway, and we supply top-quality equipment parts in New York. Over the last 30 years, we’ve witnessed how the entire parts industry has changed. In this guide, we'll cover: What initiated the equipment parts shortage Which parts are still hardest to get in 2026 What the shortage actually cost construction companies How companies are avoiding future disruptions Ready? Let’s begin. What Caused the Equipment Parts Shortage? The equipment components shortage started in 2020 when COVID-19 shut down factories worldwide. Nobody anticipated how quickly the supply chain industry could collapse until that point. How about we

Heavy Machinery Maintenance Checklist for 2026

Ever had an excavator die mid-project because someone forgot to check the hydraulic fluid? We've all been there. Equipment breakdowns derail entire job schedules, rack up rental fees, and leave your crew standing around on the clock. But the good news is, you can prevent most breakdowns with the right maintenance checklist. As a construction equipment supplier, we've seen too many companies learn this lesson the hard way. That's why we created this comprehensive guide for 2026. In this guide, we'll share practical maintenance strategies. You'll get to learn: Three types of machinery maintenance Real costs of unplanned downtime Daily, weekly, and monthly checklists Common maintenance mistakes Ways to improve your program Ready to stop throwing money at emergency repairs? Let's dive in. What Is Machinery Maintenance? Machinery maintenance is

Choosing the Right Track System for Your Excavator

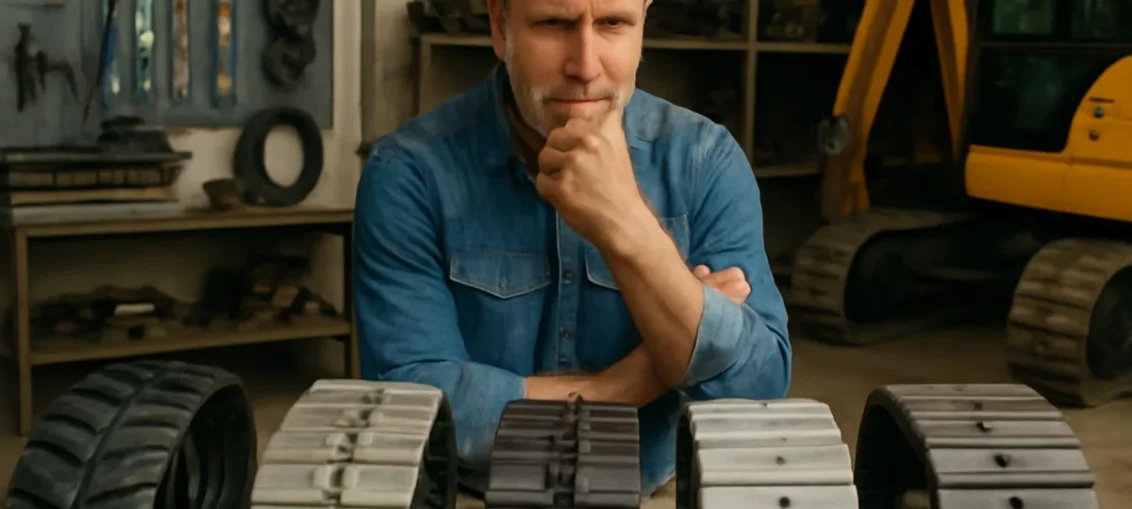

If you choose the wrong excavator tracks, you have to pay an arm and a leg for early replacements. And when you’re running an excavator on any project, your track choice becomes even more important because it affects surface protection and the working life of your machine. The right track system also cuts down repair costs, extends your equipment's working life, and keeps operators comfortable during long shifts. So you'll spend less time dealing with broken components. In this guide, we explain the differences between rubber tracks, steel tracks, and hybrid options. And, you'll also learn how to measure tracks correctly so you don't end up with parts that don't fit and maintenance habits that can double your track's lifespan. Let's get into

How to Extend the Life of Excavator Tracks

When life gets a little rocky, think about how excavator tracks have it even rockier! These poor things go through tough conditions every single day on construction sites. All that mud, debris, and rough terrain grinds away at the rubber like a cheese grater on a block of cheddar. But still, some tracks look like they’re just built differently. While a few tracks last 800 hours, others can push past 2,000 hours. It usually comes down to how you treat them between jobs, instead of the brand name stamped on the side. This guide walks you through the practical steps that stretch tracking life. We're covering the maintenance that stops costly downtime, the damage you can dodge, and the inspection checks that

How to Choose a Reliable Construction Equipment Parts Supplier

Have you ever had your excavator break down right when you needed it most? We've seen contractors lose thousands because one simple part took weeks to arrive. That’s why you need a reliable parts supplier that gets you replacement parts before you start losing money. Some suppliers promise fast delivery but leave you waiting. Others send cheap parts that break after a month, forcing you to pay twice for the same repair. This guide will show you how to choose the best parts supplier that keeps your equipment running. We'll cover inventory checks, customer service evaluation, and backup plans for when things go wrong. At Bites Off Broadway, we've been helping construction firms for over three decades by providing quality excavator parts and

5 Signs Your Excavator Needs New Parts

Nothing stalls a job site faster than a machine breakdown, especially when it’s your excavator. These heavy lifters are central to keeping projects on schedule, and any downtime can lead to missed deadlines, increased labour costs, and client frustration. Spotting those early indicators could be the difference between a simple part replacement and a costly repair that derails your entire schedule. In this post, we’ll walk through five clear signs your excavator parts are nearing failure and show you how to address them before they shut you down. Let’s get started. 1. Sluggish Hydraulic Performance in Your Excavator The first and most common warning sign you'll encounter is sluggish hydraulic performance. This is your machine's way of telling you that critical components are starting